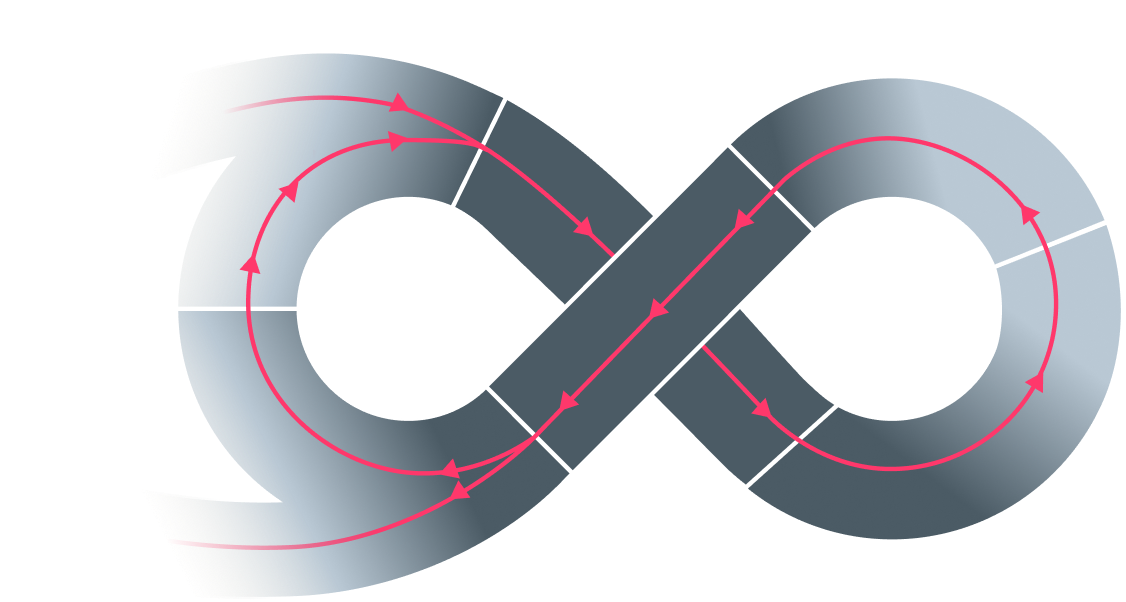

The Tire

Lifecycle

We work on a range of topics relevant to sustainability across the key-stages of the tire lifecycle; from raw-material sourcing – through manufacturing and use phases – to the management of end-of-life tires.

We developed “Sustainability Driven: Accelerating Impact with the Tire Sector SDG Roadmap” a framework for action that outlines impactful pathways for the entire sector to contribute to the ambitions of the Sustainable Development Goals (SDGs). Our research, engagement, and communication activities aim to guide, inform and support decision-making along the value chain, encourage stakeholder dialogue and inspire action-oriented initiatives among industry peers and beyond.

Discover the tire lifecycle and how the sector contributes to the SDGs.

Raw Materials

Natural rubber, primarily sourced from the rubber tree (Hevea brasiliensis), is an important raw material for the manufacturing of tires. Over 70% of natural rubber is used by the tire sector globally.

With increasing global demand for natural rubber, this is a commodity where without proper controls and standards, there can be negative impacts in the supply chain both socially and environmentally.

In 2018, we spearheaded the creation of the Global Platform for Sustainable Natural Rubber (GPSNR). GPSNR works to achieve its vision of a fair, equitable and environmentally sound natural-rubber value chain – including ensuring decent work and upholding human rights – and in doing so actively contributes to the fulfillment of the UN Sustainable Development Goals (SDGs).

Design &

Testing

Our members are engaged in continuous research and development to deliver tires that contribute to improved safety and environmental performance, including increased wet grip, reduced treadwear and rolling resistance.

Mobility innovations such as electric, connected and autonomous vehicles are transforming transport systems, and the rise of fleets, shared mobility and mass transit will lead to further business model transformation across the value chain.

These mobility trends present new opportunities for the tire sector to develop products and services that minimize negative impacts, protect the environment, promote social progress, and support economic growth.

Manufacturing

To measure, monitor and inspire sustainability in tire manufacturing operations, we commission independent reporting on our members’ environmental key performance indicators (KPIs).

Distribution

We encourage our members to accelerate and scale best practices to optimize distribution and logistics operations by using alternative fuels and implementing technologies that improve fuel efficiency, load optimization and routes (and cascade these best practices to suppliers if they manage logistics).

To read more, explore the SDG Roadmap for the tire sector.

Studying the degradation of TWRP in the environment

Sampling of TRWP in soil, air, rivers, and oceans

Investigating any potential impacts of long-term exposure of organisms to TRWP

Use Phase

Tire and road wear particles (TRWP) are tiny particles that are produced by the necessary friction between tires and the road surface.

We support cutting-edge research into the potential human health and environmental impacts of TRWP and promote action on mitigation.

Discover more about our work on TRWP at www.tireparticles.info

End-of-Life Tires (ELT)

Globally, an estimated one billion tires reach the end of their useful lives as tires every year. Managing ELT in environmentally sound and productive ways is a high priority of our members.

ELT and their materials are an inexpensive – yet valuable – resource for the circular economy. ELT can be used in a variety of applications, including as a source of energy, or for producing sport surfaces, insulation, tiles, or rubber-modified asphalt.

Follow us

Follow us on X for the latest in tire sustainability, research, and news.